The cleaning of pharmaceutical production equipment and the validation of the purification steps are time-consuming processes, and one way to speed them up is to use the fastest possible analytical techniques. Measurements using the HPLC and TOC methods are commonly used today and even if they have evolved a great deal in recent years, still need a relatively long time. Each measurement of the High Performance Ion Mobility Spectrometry (HPIMS) requires only a moment of time, therefore, the wait time for the result of the analysis can be significantly reduced, thus shortening the downtime of the machines and equipment.

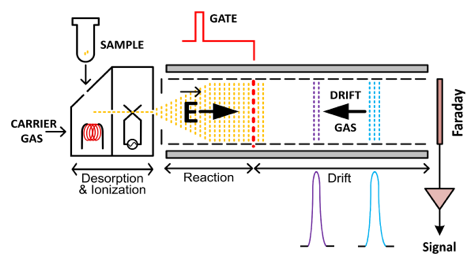

The GA2200 of Excellims Corporation in the United States ionizes the analyzed molecules and then the ions pass through an electric field in a countercurrent gas flow drift tube. The movement of smaller and lighter ions are less inhibited by the countercurrent gas molecules, thus they reach the other end of the tube sooner, which is a Faraday plate that also serves as a detector. The impact of the larger ions occurs at a later point in time, but the time required for one measurement can still be measured in milliseconds.

The analytes can be identified qualitatively and quantitatively, and appropriate calibrations must be established prior to these measurements. For qualitative identification the drift time values can be used, which are constant for ions of a given size and shape under the same measurement parameters – temperature, voltage and pressure. Calibration curves based on peak height or area can be used for quantitative analysis, however, these values also depend on the chemical environment. Accurate quantification, therefore, requires the use of calibration samples in which the component to be tested is located in a matrix whose composition is as close to that of the actual sample to be measured as possible.

The GA2200 has a compact design and it is controlled with a touch screen. The relatively small size of the instrument allows it to be placed on a trolley/table and moved quickly between production rooms or among equipment. Because it requires minimal sample preparation, measurement can be carried out even at the cleaning site, avoiding the movement of the samples between laboratories and buildings. In the case of liquid samples, the default ionization mode is electrospray ionization, while in the case of swab samples, thermal desorption is also possible. The typical sensitivity of the instrument is in the range of ppb – ppm, and the linear range covers 2 – 3 orders of magnitude. The software of the instrument is 21 CFR Part 11 compliant, and the measurement results can be saved and archived on an external storage unit.

Specifications:

- analysis time: 30 – 60 seconds

- sensitivity: ppb – ppm / pg – ng

- linear range: 2 – 3 orders of magnitude

- ion source: electrospray (ESI) or thermal desorption

- drift tube: 10 cm

- drift gas temperature: max 250 °C

- drift gas: air free of oil and other pollutants, N2, CO2, other inert gas

- gas consumption: max 3.5 liters/minute

- dimensions: 47 x 41 x 47 cm, 19 kg

- control: built-in Windows-based computer with touch screen

- software: VisionTM control and data evaluation program with 21 CFR part 11 compliance