When the company accroma labtec Ltd. was founded in Muttenz, near one of the centers of innovative pharmaceutical companies Basel, the employees set the goal of creating an instrument that supports pharmaceutical analysis and which can perform the time-consuming and unmanageable sample preparation processes automatically, without any human intervention. The result of their developments is the accroma® SamplePrep 2.0 system, which can be effectively used to determine the active ingredient content and the content uniformity of various pharmaceutical products, for stability tests, but also for the examination of pharmaceutical counterfeits or for example also for sample preparations of food pesticide residues using the QuEChERS method.

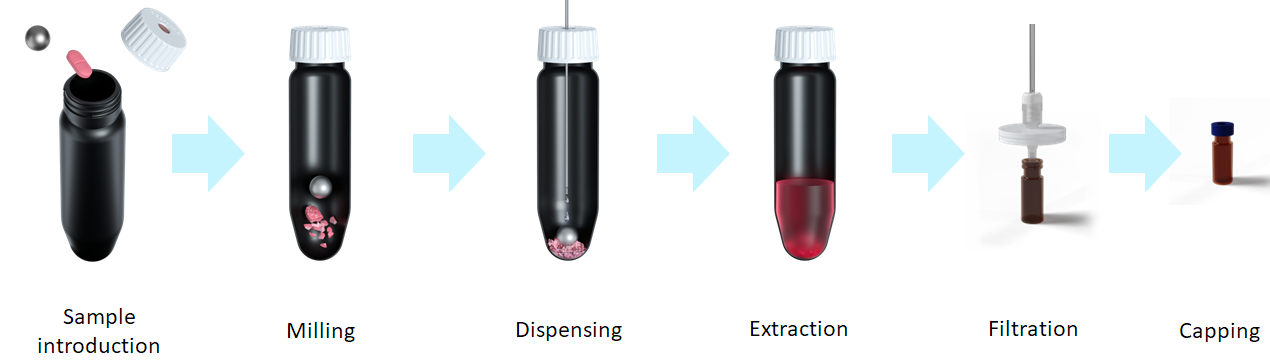

The workstation with its modular structure is capable of measuring the initial mass of the samples, of homogenization, grinding, solvent dosage, solution, dilution, filtration, optional ultrasonicating and centrifugation. The samples prepared in this way can be transferred into the HPLC autosampler automatically or to the appropriate analytical instrument manually.

The central element of the accroma® 2.0 system is a robotic arm that moves the tubes containing the samples between the modules built around it. For the safety of the system and the users, during operation the instrument is closed with a door, thus ensuring smooth operation.

The central element of the accroma® 2.0 system is a robotic arm that moves the tubes containing the samples between the modules built around it. For the safety of the system and the users, during operation the instrument is closed with a door, thus ensuring smooth operation.

The samples are processed in 120 ml high density polyethylene (HDPE) tubes. A total of 64 tubes for samples can be placed in the tube rack, where 60 additional places are reserved for various liquids (stabilizer, modifier, solvent, etc.), syringe filters and centrifuge counterweights

Between the various steps, the weight of the sample tubes can be continuously monitored with the built-in weigh module, from the taring of the sample holder tubes and sample insertion to the filtration.

A ball mill is used to homogenize and dissolve the samples. The faster and more complete crushing and dissolution of the samples is aided by the stainless steel balls that can be placed in the tubes. With their help even the samples placed in the glass ampoules can be extracted after the balls break the glass containers in the tubes.

The sample preparation system disposes of a second homogenizing place as well, where an ultrasonic bath or a second ball mill can be optionally placed. The ultrasonic bath has 1 tube position and is capable of drying the outer side of the tubes that have been removed from the water bath.

For solvent and other liquid dosing, the workstation has 2 micro annular gear pumps, which can be used to dose up to 8 types of solvents in the solvent container and additional liquids placed into the tube holder rack. The exact quantity of the dispensed liquids is determined and documented by weight measurement in the weigh module.

The samples dissolved and containing little suspended material can be filtered through a syringe filter and the filtrate can be collected in a snap ring type HPLC vial. The inhomogeneous samples can be separated before filtration with the optionally available centrifuge, and due to the adjustable pipette height, only the clear solution will be used for filtration. After collecting the filtrate, the workstation also caps the vial.

The samples dissolved and containing little suspended material can be filtered through a syringe filter and the filtrate can be collected in a snap ring type HPLC vial. The inhomogeneous samples can be separated before filtration with the optionally available centrifuge, and due to the adjustable pipette height, only the clear solution will be used for filtration. After collecting the filtrate, the workstation also caps the vial.

The filtrate collected in the HPLC vial, ready for analysis, can be placed in the vial holder by the robot arm, from where it can be manually transferred to the appropriate analytical measuring instrument at the end of the workflow. Optionally, if a compatible HPLC is available, the robot arm places the vial directly into the automatic sampler of the HPLC and the given HPLC injector performs the injection of the sample. After the injection, the HPLC vial is returned to the vial holder of the accroma® 2.0.

The system is controlled by the accrolab software, which ensures compliance with the regulations of 21 CFR Part 11. With the drag&drop system, the steps performed with the various modules can be easily and transparently organized into a workflow. The workflows can be assigned to different tubes within a system launch, thus it is possible to run the same or different workflows for all samples. The software keeps a detailed log of the steps for the samples and the results of the measurements. Due to the advanced time optimization algorithms, the accrolab is able to increase the sample throughput by overlapping the steps of consecutive samples.

All these features can result in significant time savings of up to 80-90% within the otherwise lengthy process of sample preparation. According to the examples of downloadable applications, for instance in the case of Rosuvastatin and Levothyroxine sodium tablets, the approximately 30-minute sample preparation procedure can be reduced to only 5 minutes. The 15-20-minute-long sample preparation steps required to determine the sodium benzoate content of various creams and ointments can be reduced to 3-5 minutes. The QuEChERS sample preparation process, which is important in food safety measurements, can also be completed within a significantly shorter time.