The German company Kraemer Elektronik GmbH has been manufacturing instruments for testing various pharmaceutical forms since 1985. The P-series semi-automatic instruments are designed to determine the dimensions, the breaking force (hardness) value and weight of tablets and capsules. Before starting the test, up to 20 tablets must be placed manually, one by one, in the positions of the turntable, and then, after setting the parameters, the instrument transfers, positions, measures and evaluates the results automatically. The tablets or capsules are moved and oriented not only by rotating the carousel, but also by the VibrALIGN vibration system built into the position of the measuring cell. The operating parameters of the VibrALIGN, such as the strength and time of the vibration, can be adjusted individually to the most optimal values for different products. The measuring cell can crush tablets at a constant speed or by applying a constant force and thus it can determine the breaking force value. The speed is freely adjustable between 0.1 – 8 mm/sec and the force is freely adjustable between 1 – 100 N/sec.

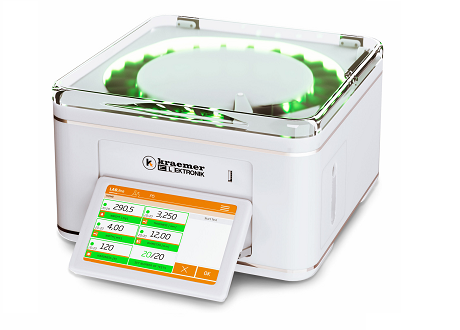

The P-series instruments are controlled by a 7’’ touch screen. The measurement parameters, the tolerance and acceptance ranges can be recorded per product. The large internal memory allows the storage of data for approx. 10,000 products. The measured values can also be displayed graphically, histograms and breaking force (N) – displacement (mm) or breaking force (N) – time (sec) graphs can also be displayed. The methods and results are stored in a database, which can be saved and restored as well. The instrument has both USB and network connectors. The results can be saved onto a portable data storage device, but it is also possible to attach a network drive. In the latter case, the results can also be saved in CSV or XML format into a designated network directory, thus making them readable to LIMS systems (optional).

The number in the name of the instruments refers to the measurable parameters, thus the P3+ measures the breaking force, the diameter (length) and thickness. The P4+ also measures the weight of the tablet with its built-in scale, and the P5 can rotate the tablet and is, therefore, also suitable for determining the width. Each has an easily removable collector and an easy-to-clean surface, and a LED row running around the entire surface provides feedback on the operation. The load cell of the instruments can be calibrated with calibrated weights or with a dynamic manual calibration unit within the entire measuring range.

Specifications:

- control: 7’’ touchscreen

- connections: 3 x USB 2.0 / 1 x RJ45 LAN / 1 x RS-232

- printing: network or USB printer with PCL6 compatibility

- dimensions: 320 x 320 x 185 mm, approx. 15 kg (depending on configuration)

breaking force (hardness):

- measurement mode: constant speed (0.1 – 8 mm/sec) or constant force (1 – 100 N/sec)

- measurement range: 4 – 400 N

- accuracy: ±1 N

- resolution: 1 N

- measurement unit: N, Kp, Sc

diameter / length / width:

- measurement range: 2 – 22 mm

- accuracy: ±0.05 mm

- resolution: 0.01 mm

- measurement unit: mm, inch

thickness:

- measurement range: 1 – 12 mm

- accuracy: ±0.05 mm

- resolution: 0.01 mm

- measurement unit: mm, inch

weight:

- built-in Sartorius scale

- measurement range: 0.01 – 10 g

- accuracy: ±1 mg

- resolution: 0.1 mg