With the use of autosamplers, the capacity of HPLC systems and the reproducibility and reliability of the analyses can be increased. The LC-4000 series has 4 types of autosamplers which differ from each other considering the usable pressure limits, the number of the samples, the methods of liquid moving and the washing modes. Each instrument is equipped with a door opening and leak detector, volume compensation configuration option, rack identification, vial detection and internal/external needle washing option. The thermostatting of the samples is carried out with an optional thermostat unit. The use of the modules in any chromatographic system is helped by the three electric signals that are emitted in the moment of the injection via three independent connectors, so that the various modules and data processing can be started simultaneously with the injection. The AS modules have built-in control units, the operation parameters can be adjusted with buttons. 10 programs can be stored in the internal memory of the instruments and each of the programs may contain max. 64 steps. With the JASCO ChromNav2 software the autosamplers can be fully controlled.

AS-4050/4050i autosampler – 60-place standard sample holder

AS-4050 standard configuration, 60-place (2 ml vial) autosampler used for conventional chromatographic applications (max. 30 MPa). Optionally, it is possible the use of 4; 0.6 and 0.3 mL vials, Eppendorf tubes and also 96 or 384-place microplates and Deep Well plates. The full injection mode provides excellent reproducibility for serial measurements, as it uses the complete loop filling technique. For method development and optimization the partial injection mode is favorable, because the volume of the injected sample can be changed without replacing the loop. The fluid moving is carried out by the syringe placed at the front of the instrument. The drainage of the washing is done by gravity. The optionally installed Auto Drain unit operating with a vacuum pump allows a more efficient drainage of the washing liquid as well as the washing of the injector port, thus reducing the cross-contamination.

For metal-free analyses the AS-4050i bio-inert autosampler can be used, as the surfaces that come into contact with the liquid are Teflon, PEEK, glass and ceramics. The instrument is equipped with a built-in Auto Drain unit. For this instrument the use of pre-split septa have to be used because of the ceramic needle.

AS-4150/4250 autosampler – 180-place standard sample holder

In the case of the AS-4150 (max. 70 MPa) autosamplers used for rapid chromatographic applications as well as the AS-4250 (max. 130 MPa) ones used ultra-high pressure  chromatography in standard configuration 180 2 ml vials can be placed into the sample holder. However, with different sample holder racks it is possible the use of 4; 0.6 and 0.3 ml vials, Eppendorf tubes and 96 or 384-place microplates and Deep Well plates. Similarly to the AS-4050 sampler, these instruments have partial and full injection modes, but optionally it is possible the use of the direct injection mode, which provides faster injection. These autosamplers can be used not only for the automation of the analysis, but also of the sample preparation process: for derivatization, dilution, mixing. In both models the liquid moving is performed by the metering pump. They have a built-in Auto Drain unit, thus beside the inner and outer needle wash it is also possible to wash the injector port. With the optional multi-solvent washing option the cross contamination can be reduced to less than 0.005%, while with the built-in degasser module the washing liquids can be degassed.

chromatography in standard configuration 180 2 ml vials can be placed into the sample holder. However, with different sample holder racks it is possible the use of 4; 0.6 and 0.3 ml vials, Eppendorf tubes and 96 or 384-place microplates and Deep Well plates. Similarly to the AS-4050 sampler, these instruments have partial and full injection modes, but optionally it is possible the use of the direct injection mode, which provides faster injection. These autosamplers can be used not only for the automation of the analysis, but also of the sample preparation process: for derivatization, dilution, mixing. In both models the liquid moving is performed by the metering pump. They have a built-in Auto Drain unit, thus beside the inner and outer needle wash it is also possible to wash the injector port. With the optional multi-solvent washing option the cross contamination can be reduced to less than 0.005%, while with the built-in degasser module the washing liquids can be degassed.

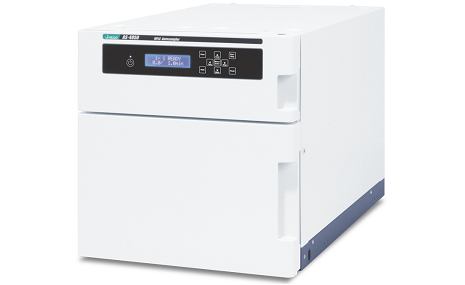

AS-4058 preparative autosampler – 40-place sample holder

The AS-4058 autosampler used for preparative chromatographic applications in standard configuration is capable of including 40 20 ml vials, however, optionally it is also possible the use of 4, 6, 10 or 27 ml vials. It has a built-in Auto Drain unit, thus beside the inner and outer needle wash it is also possible to wash the injector port. With the optional multi-solvent washing option the cross-contamination can be reduced to less than 0.02%, while with the built-in degasser module the washing liquids can be degassed.